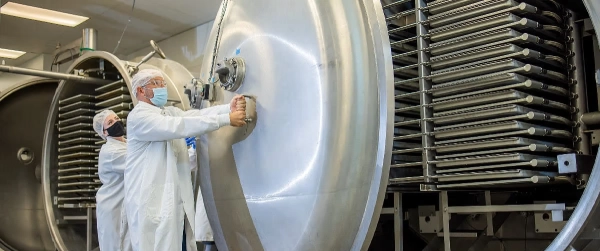

Freeze-drying, also known as lyophilization, is a process in which water in the form of ice under low pressure is removed from a material by sublimation.

Silicone oil is used as a thermal fluid in the freeze-drying (lyophilization) process, transferring heat energy to products. This process, which involves freezing and then applying heat, circulates silicone oil through lyophilizer shelves to maintain the desired temperature.

Lyophilization is utilized in medicine, pharmaceuticals, biological research, chemicals, and food production, preserving products for long-term storage while maintaining their original biochemical characteristics.

Over time, lyophilizer conditions can cause leaks, contaminating products with silicone oil, posing a safety threat. To prevent this, some lyophilizers can detect small traces of silicone oil, and technologies like mass spectrometry can identify both silicone oil and external air leaks.

Mass Spectrometer:

A non-invasive method for detecting minimal amounts of silicone oil, suitable for continuous monitoring. Enhanced detection can be achieved by lowering pressure, increasing shelf temperature, and closing the main valve or turning off condenser cooling. Connect the mass spectrometer to a chamber port with a hose for direct operation.

In Situ Detector for Coolant Vapors:

Detects silicone oil signatures, process states, and small leaks during operation. If a leak is detected, a helium leak test can locate the source.